| Issue |

Renew. Energy Environ. Sustain.

Volume 7, 2022

|

|

|---|---|---|

| Article Number | 18 | |

| Number of page(s) | 10 | |

| DOI | https://doi.org/10.1051/rees/2022006 | |

| Published online | 24 June 2022 | |

Research Article

Effects of roof angle, inlet gap size and dryer height on temperature and relative humidity in a chimney-dependent solar crop dryer

1

Department of Mechanical Engineering, College of Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

2

Department of Mechanical Engineering, Kumasi Technical University, Kumasi, Ghana

* e-mail: tonyagyemang@yahoo.com

Received:

3

February

2022

Received in final form:

9

April

2022

Accepted:

9

April

2022

A chimney dependent solar crop dryer (CDSCD) was developed and studied. Design of Experiment (DOE) was employed using statistical three level non randomized factorial experimental design in Minitab statistical software version 19.0. The study of effects of roof angle, inlet gap size and dryer height on dryer temperature revealed that the height at which the drying tray is positioned (A) and the inlet gap (C) influences the highest temperature difference, 30.4 °C. It was concluded that dryer temperature is high when the inlet gap is small (range of inlet area to exit area ratio of 1.8128:1 to 1.0877:1) and the maximum ratio of height of dryer to drying tray’s position is 2.18. Optimal values for achieving high temperature difference response greater than or equal to 32.6 °C are minimum roof height of 84 cm, inlet to outlet area ratio of 1.0877:1 and minimum roof angle of 81°. The effect of the three parameters on relative humidity revealed that the combined effect of roof angle and inlet gap (AB) attained the highest standardized effect of 6.6. The optimal values for achieving low dryer relative humidity (when loaded with 1 kg of cassava) were roof angle of 64°, inlet to outlet area ratio of 2.5379:1 and minimum time of 19 hours. This could serve as effective tool for comparing different designs of CDSCD dryers for optimum humidity and drying performances and be used to subsequently refine solar crop dryer design.

Key words: Solar dryer / roof angle / nlet gap size / factorial design / dryer temperature / Ghana

© A. Agyei-Agyemang et al., Published by EDP Sciences, 2022

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Drying is one of the oldest methods of preservation. Drying is a common method for food preservation, especially for vegetables and fruits [1]. It is done by removing moisture from a product and it is used to preserve foods and extend their shelf lives. The shelf life of a food product can be prolonged by the reduction of its water activity [2]. The objective of drying as a thermal engineering is to remove the free water along with the bound water in a product without causing any sort of chemical changes to its composition [3]. In addition to reduction of moisture, drying also changes some properties like antioxidant capacity, enzymatic activity, aroma, and flavour of the product [4]. Maize grains, chili pepper, cassava tubers, and beans are usually dried and consumed in Ghana. Foods that are not well dried are susceptible to infections [5].

Some microorganisms on foods produce toxins that are dangerous to human health. They are usually bacterial, phyco- and mycotoxins [6]. Mycotoxins are produced by Aspergillus, Fusarium, Alternaria and Penicillium [6]. Mycotoxins belong to the fungus kingdom [7]. Contamination of mycotoxins in crops could take place anytime in the life of food products, from the farm through harvest to storage [6]. Food products contaminated with aflatoxins have received a lot of attention globally of late, since they have been found to endanger human healthy lifestyle and commodities in international trade [8]. Aflatoxins are heat-stable molecules and can therefore not be easily eliminated using different heat treatments, therefore prevention of their formation is essential [9]. Rapid drying of Agro-products to reduce their moisture content prevents the formation of favourable conditions for the growth of the fungi [9]. The level of harm caused depends upon the dose of contamination of fungal toxins. Lower doses of fungal toxins in food could lead to long term severe health effects, including cancer and immune deficiency [10]. Studies have revealed that good drying process could improve food quality and take out major toxic fungi [5]. It is therefore necessary to develop such drying processes that prevent not only formation of these toxic substances, but also influence good characteristics of the product.

Drying is a very energy intensive process [8], therefore a small increase in its energy efficiency will contribute positively to the industry’s sustainable development. There are different drying methods in use today. Hot air drying (HA) is an effective method for drying, however, it operates at high temperature which usually causes degradation of useful nutrients and colour [9]. Vacuum freeze drying (VF) has been researched and applied to food crop drying and has been observed to lead to much less losses in the nutrients as compared to high heat treatments [11]. Other methods of improved drying of foods are combined infrared and hot air-drying technology [12], radio frequency, vacuum and osmotic drying techniques [13], sequential infrared blanching and hot airdrying technique [14], as well as the use of microwave techniques [11]. These drying methods may be very good but are beyond the reach of average farmers in a poor country. It is therefore necessary to study and improve simple and less expensive drying methods and make them more efficient.

Drying methods and types of dryers are classified on different basis. They include heat source, heat transfer method to the material being dried, properties of material being dried, how they operate, how drying medium moves relative to the material being dried [15]. However, since drying is energy intensive operation, using heat source or energy source is an important way of classification [16]. Drying, mainly due to its high energy demand in terms of thermal energy, is known to be one of the most energy-intensive processes [17].

In Ghana, food crops drying is mainly classified into three; open sun drying, mechanical drying, and solar drying. Open sun method involves introduction of a product to direct sunlight to remove moisture from it. For drying to take place, the relative humidity of the surrounding air should be less than the level of equilibrium moisture content of the product [18]. Should the relative humidity be above the equilibrium moisture content level of the product, it would rather absorb moisture instead [18]. Open sun method is used for drying in most rural settings, because it is simple and costs relatively less. However, it turns out poor quality products, owing to its reliance on weather and its vulnerability to dust, dirt, rain, insects, pests and micro-organisms [19].

In mechanical drying, heat is introduced artificially to increase drying medium’s temperature in order to remove moisture from a product. The heat source is usually fossil fuels and electricity. Solar dryers, the third group, come in different types, classes and designs. They are classified into three distinct categories based on mode of heat transfer from the sun to the product. They are direct mode, indirect mode, and mixed mode solar dryers. Direct mode solar dryers are often cabinets covered with transparent material that are able to absorb and retain heat. Indirect mode dryers have two main chambers; the collector, which generates heat by trapping and retaining heat from the sun, and the drying chamber where the product is placed for drying. During the drying process heat is supplied by hot air flowing through the chambers, and carries evaporated moisture from the product out of the dryer. The mixed mode solar dryer is designed to combine both direct and indirect mode dryers. Indirect solar dryers are more effective than conventional open sun drying and direct solar dryers since they produce good quality products in less drying period [20]. However, mixed mode is the best as far as drying time is concerned [21].

Studies on postharvest losses estimates losses to be about 40%, which under worse conditions could rise to about 80% [22]. Only about 60% to as high as 74% of all maize harvested, for example, get to the consumer [23]. Maize a very important food crop suffers a lot of postharvest losses right from harvesting stage to the point where it gets into the hands of the final consumer. Drying could be a good solution. Relatively, mechanical dryers are better alternative for drying agricultural produce, but they need fuel to operate. Availability of fuel and their continuous price increase, discourage promotion and use of mechanical dryers. Solar dryers could serve as a bridge between mechanical and traditional drying methods since it is relatively cheap and simple compared to mechanical dryers, and they dry products in more hygienic conditions compared to traditional drying method.

To make a solar dryer more effective, a chimney may be added to the design. Solar dryer with a chimney allows improved ventilation. A solar dryer which has a drying chamber with inclined roof and chimney combined with suitable inlet exit area ratio was observed to improve flow of air in the direct mode dryer [24–28]. Such a solar dryer works on the principle that in operation, radiant energy of short wavelength from the sun is transmitted through transparent drying chamber and chimney glazing to fall on absorbers in the dryer. Heat absorbers, after absorbing this radiant energy, in turn emit heat energy of long wavelength that gets trapped but does not pass through the glazing back into the atmosphere. The trapped energy heats up air in the chamber and chimney, which then effectively dries the product in the drying chamber. That is, cold air flows through the inlet, gets heated up and dries crops inside the chamber. In the process, the air becomes more humid after moisture absorption from the crops and flows through the solar chimney where it gets heated again, becomes less dense and is then driven upwards to exit through the top vent into the surroundings, effecting continuous flow where cold, dense air is drawn in to displace the warm air through the dryer [24–28]. Other researchers have confirmed that properly designed solar chimney boosts flow of air through an enclosure [29–33].

In this study, direct solar dryer with a chimney was designed. The direct mode dryer, unlike its two other counterparts, is highly influenced by ambient relative humidity, according to Afriyie [24], and therefore in geographical locations of persistently high ambient relative humidity, the chimney is not very significant in influencing drying rate. It is therefore important to investigate for a particular geographical area, the effect of chimney height, among other things, for the prevailing relative humidity conditions, on drying processes, else building chimney dependent solar crop dryer (CDSCD) could be waste of resources. Afriyie [52] observed that relying on one particular feature of CDSCD for performance improvement may render the dryer uneconomical or unstable, and therefore suggested that reasonable moderate changes in two or more features or design characteristics could be the best method of improvement of CDSCD. Design of experiment (DOE) was therefore chosen as the tool to study combined effects of two or more features on the dryer. Using design of experiment (DOE), influential parameters were varied to study how such a simple dryer could be improved and optimized.

The aim of this study was to investigate effects of roof angle, inlet gap size and dryer height on temperature and relative humidity in a chimney-dependent solar crop dryer (CDSCD) using design of experiment (DOE) method to inform future design improvements. Design of experiment (DOE) is a systematic, efficient method that enables scientists and engineers to study the relationship between multiple input variables and key output variables. It is therefore very good and effective in multi-factor study of the combined effects of the factors on the design of a commodity under study. DOE was used also to reduce the cost of conducting several physical experiments.

2 Materials and methods

2.1 Experiments

Experiments were conducted using dryer dimensions and physical experimental works of Afriyie et al. [26]. A laboratory scale direct mode dryer was developed and constructed. Three different drying chamber roofs, oriented at the following angles to the vertical plane: 51°, 64° and 81°, were developed and used interchangeably. Geometric dimensions of the base of drying chamber are 420 mm × 440 mm with the width normal to the air flow and height of 1090 mm. The glazing material used for the drying chamber walls was Lexan sheet of thickness of 2 mm.

Source of heating was eight pieces of 100 W infrared lamps which were installed in front of the dryer to simulate solar irradiation. Six thermocouple probes were positioned in the dryer to take the temperature of air at various heights (H1 = 6 cm, H2 = 16 cm, H3 = 26 cm, H3 = 49 cm, H4 = 84 and H1 = 109 cm). Ambient and dryer outlet temperatures were measured using thermometers. Air inlet gap size was varied from 30 mm, through 50 mm to 70 mm. Figure 1a shows an illustration of the functional architecture of a chimney-dependent solar crop dryer (CDSCD) and Figure 1b shows the pictorial view of its laboratory setup. Cassava was used for the experiment because it was readily available on the market. One (1) kilogram of cassava was cut into pieces to form quadrants with 15 mm thickness and average radius of 30 mm. The drying trays carried 0.5 kg of cut cassava each and were positioned at a height of 150 mm above the base of drying chamber. In each drying process, lamps were put on for seven (7) hours in the day during which data were logged every hour. The lamps were then switched off and the dryer left alone throughout the night till the next morning when the weight of crop was noted before drying resumed. This was to examine night performance of the dryer without any irradiation. Temperature, air velocity and relative humidity values were measured in the process.

|

Fig. 1 Functional architecture and pictorial view of chimney-dependent direct mode solar crop dryer. |

2.2 Design of experiments

In this study, drying experiments were planned using statistical three level non randomized factorial experimental design with no replicate. Experiments were carried out by considering five drying parameters: Roof angle (°), Inlet gap size (mm), drying height (cm), temperature (°C) and relative humidity (%). Total runs were 54 for the temperature effects and 225 for the relative humidity effects experiments. Table 1 shows the design summary for experiments carried out. The experimental matrix for effects of roof angle, inlet gap size and height on temperature is presented in Table 2, while that of effects of roof angle, inlet gap size and height on relative humidity is presented in Table 3.

In two experiments the factors, roof angle and inlet gad had three (3) levels each, the dryer height had six (6) level values, and time had twenty-five (25) level values. Design of experiments was carried out using Minitab statistical software, version 19.0. For the purpose of this study the temperatures mentioned refers to the temperature differences between the ambient and the measured dryer temperatures.

Design summary for the temperature and humidity effects experiments.

Experimental matrix for effects of roof angle, inlet gap size and height on temperature.

The experimental matrix for effects of roof angle, inlet gap size and height on relative humidity.

3 Results and discussions

This section discusses factorial design analysis of the study. This includes effects of roof angle, inlet gap size and height on dryer temperature, and then effects of roof angle, inlet gap size and height on relative humidity.

3.1 Effects of roof angle, inlet gap size and height on dryer temperature

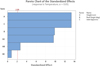

Figure 2 is a Pareto chart of standardized effects. The Pareto chart shows that height (A) and inlet gap (C) of the dryer have the highest statistically significant standardized effect of 13.4. Roof angle (B) which is the third in order also has statistically significant influence on dryer temperature, with standardized effect of 9.9. Effects of height and inlet gap (AC) attained standardized effect of 9.6. Dryer height and dryer roof angle effects (AB) had the least significant standardized effect of 2.6. Effects of dryer roof angle and dryer inlet gap (BC) had insignificant standardized effect of 0.8. Insignificant because it did not cross the reference line (2.09). Aforementioned factors and effects analyzed except effects between roof angle and inlet gap should be considered in dryer as they influence drying temperature.

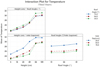

Contour plot of temperature versus inlet gap and height is shown in Figure 3a. Figure 3 shows that increasing dryer height whilst reducing inlet gap resulted increase in temperature difference. Combined effect of inlet gap and dryer height shows increase in dryer temperature when inlet gap is in the range 30–50 mm and the height is above 50 cm. Main effect plot of temperature is presented in Figure 3b. It shows that height significantly influences the highest temperature difference (30.4 °C) (at height of 109 cm or height of dryer to dryer’s height position of 1) whilst the dryer inlet gap and roof angle attained maximum temperature difference of 28.6 °C (at the low inlet gap of 30 mm) and 27.3 °C at high roof angle of 81°. To achieve a high dryer temperature, inlet gap range of 30–50 mm with a height above 50 mm and minimum roof angle of 81° is required. Considering a given width for both dryer inlet and outlet, the optimal area ratios for high drying temperatures is 1.8128:1 to 1.0877:1. Further the maximum ratio of height of dryer to drying tray’s position is 2.18 with an optimum high roof angle of 81° is recommended in similar dryer design.

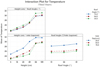

Figure 4 shows interaction plot (plot of combine effects) of temperature as influenced by roof angle, height and inlet gap size. Plot of combine effects shows that effects between height and roof angle was such that there was rise in temperature difference with respect to the various roof angles as the height in the dryer increases. Maximum temperature difference was recorded at roof angle of 81° and height of 109 cm. Combine effect between height and inlet gap of the dryer showed that with increasing height (6 cm to 109 cm) and reducing inlet gap (up to 30 mm), the dryer temperature difference increases by 31.7 °C. Furthermore, roof angle and inlet gap effects resulted in an increased dryer temperature difference. The inlet gap and roof angle when adjusted to 30 mm and 81° yield a high dryer temperature difference of 29 °C. It is observed that combine effects plot (Fig. 4), Pareto chart of standardized effects (Fig. 2), contour plot of temperature versus inlet gap and height (Fig. 3a), as well as main effects plot of temperature (Fig. 3b), are all in good agreement.

Table 4 presents computed analysis of variance results for effects of roof angle, inlet gap size, and dryer height on temperature. P-value for each term (roof angle, inlet gap, and time) is less than 0.005 which is statistically significant and this explains variation in the temperature difference response. These regression results show satisfactory fit of model variability for the dryer temperature difference. Hence the regression model can be used to predict the CDSCD dryer temperature. Optimization response prediction presented in Figure 5 shows the optimal values which will maximize drying temperature. The optimal values for achieving high temperature difference response greater than or equal to 32.6° are a height of 84 cm, inlet gap of 30 mm and a roof angle of 81°.

|

Fig. 2 Pareto chart of standardized effects (temperature response). |

|

Fig. 3 Contour plot of temperature versus inlet gap and height and main effects plot for temperature. |

|

Fig. 4 Interaction (Combine effects) plot for temperature. |

The analysis of variance results for effects of roof angle, inlet gap size, and dryer height on temperature.

|

Fig. 5 Optimization plot. |

3.2 Effects of roof angle, inlet gap size and height on relative humidity

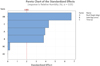

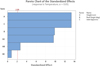

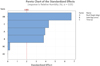

Pareto chart of standardized effect presented in Figure 6 shows the relative humidity response. Combine effect between the roof angle and inlet gap (AB) recorded the highest standardized effect of 6.6 which is beyond the reference line of 1.985 The next is drying time (C) with standardized effect of 4.4, followed by roof angle (A) with standardized effect of 3.9. Standardized effect of dryer inlet gap (B) was 3.8. Both effects between inlet gap and time (BC), and roof angle and time (AC) had statistically insignificant effect on relative humidity of the dryer since their standardized effects (0.2 and 0.0 respectively) fall below the reference line (1.985).

Main effects and combine effects plots for relative humidity are presented in Figure 7a and 7b. Figure 7 shows main effect plot of the relative humidity. The main effect plots show that time has highest effect on relative humidity inside the dryer as compared to roof angle and inlet gap. From Figure 7b, combine effects between the roof angle and inlet gap shows the following factors as good candidates for reduced relative humidity in the dryer: 64° roof angle with 70 mm inlet gap, and 81° roof angle with 30 mm inlet gap. Reduced dryer relative humidity accelerates drying process by increasing the moisture absorption potential of hot air in the dryer cite. Results from temperature effects and combine effects plots show that 81° roof angle with 30 mm inlet gap yields the highest mean dryer temperature difference. Hence, the most appropriate roof angle and inlet gap size to select for increased mean dryer temperature and reduced relative humidity are 81° roof angle and 30 mm inlet gap size.

Table 5 gives analysis of variance results for effects of roof angle, inlet gap size and height on relative humidity. P-value for each term (roof angle, inlet gap, and height) is less than 0.005 which is statistically significant and this explains variation in the humidity response. These regression results show satisfactory fit of the model variability for the dryer relative humidity. Hence the model can be used to predict dryer relative humidity.

Figure 7c presents relative humidity optimization results. The results show that optimal values for achieving reduced dryer relative humidity response (when loaded with 1 kg of cassava) are roof angle of 64°, inlet gap of 70 mm and minimum time of 19 h. Inlet gap of 70 mm corresponds to inlet cross-sectional area of 0.07 m × 0.39 m or 0.0273 m2. The exit cross-sectional area was 0.03 m × 0.39 m with two (2) semi circles of 15 mm radius on either side, giving total cross-sectional area of 0.0107568 m2. Thus, the optimum inlet to outlet area ratio was 2.53792:1.

|

Fig. 6 Pareto chart of standardized effects (relative humidity response). |

|

Fig. 7 Main effects plot, interaction (combine effects) plot and optimization for relative humidity. |

The analysis of variance results for effects of roof angle, inlet gap size and height on relative humidity.

4 Conclusion

The study of the solar crop dryer was successfully conducted using Design of Experiment (DOE). It can be concluded that dryer temperature is high when the inlet gap is small (that is when inlet to exit area ratio is between 1.8128:1 to 1.0877:1) and height is above 50 cm (that is, the maximum ratio of height of dryer to drying position is 2.18). The optimal values for achieving high temperature difference response greater than or equal to 32.6 °C, are minimum dryer height of 84 cm (the maximum ratio of height of dryer to drying tray’s position is 1.30), an inlet to outlet area ratio of 1.08768:1 and a minimum roof angle of 81°. Thus, inlet gap of 30 mm (or inlet to exit area ratio of 1.0877:1) was better as relative humidity was much lower, overriding the effect of airflow restriction at inlet. Optimal values for achieving reduced dryer relative humidity (when loaded with 1 kg of cassava) are a roof angle of 64°, an inlet to outlet area ratio of 2.53792:1 and a minimum time of 19 hours. The findings can inform better design decision, and be used as a tool for comparing different designs of CDSCD dryers for optimum humidity and drying performances.

Future work may focus on the use numerical methods (CFD) to investigate the aforementioned effects and conduct further design improvements and subsequently develop experimental setup based on the findings of the study.

References

- M.R. Vishnuvardhan, V.P. Chandramohan, Comparison of drying kinetics, thermal and performance parameters during drying guava slices in natural and forced convection indirect solar dryers, Sol. Energy 234, 319–329 (2022) [CrossRef] [Google Scholar]

- H. Moussaoui, M. Kouhila, H. Lamsyehe, A. Idlimam, A. Lamharrar, Moisture sorption measurements and thermophysical characterization of the Taraxacum officinale leaves and root, Heat Mass Transf. Und Stoffuebertragung (2020) https://doi.org/10.1007/s00231-020-02838-5 [Google Scholar]

- H. Moussaoui, Y. Bahammou, Z. Tagnamas, M. Kouhila, A. Lamharrar, A. Idlimam, Application of solar drying on the apple peels using an indirect hybrid solar-electrical forced convection dryer, Renew. Energy 168, 131–140 (2021) [CrossRef] [Google Scholar]

- N. Jiang et al., Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption, LWT-Food Sci. Technol. 82, 216–226 (2017) [CrossRef] [Google Scholar]

- F. Xing et al, Distribution and variation of fungi and major mycotoxins in pre-and post-nature drying maize in North China Plain, Food Control 80, 244–251 (2017) [CrossRef] [Google Scholar]

- E. Nuroğlu, E. Öz, S. Bakırdere, E.O. Bursalıoğlu, H.B. Kavanoz, O. İçelli, Evaluation of magnetic field assisted sun drying of food samples on drying time and mycotoxin production, Innov. Food Sci. Emerg. Technol. 52, 237–243 (2019) [CrossRef] [Google Scholar]

- M.H. Taniwaki, J.I. Pitt, N. Magan, Aspergillus species and mycotoxins: occurrence and importance in major food commodities, Curr. Opin. Food Sci. 23, 38–43 (2018) [CrossRef] [Google Scholar]

- M. Moradi, M. Azizi-Lalabadi, P. Motamedi, E. Sadeghi, Electrochemical determination of T2 toxin by graphite/polyacrylonitrile nanofiber electrode, Food Sci. Nutr. 9, 1171–1179 (2021) [CrossRef] [Google Scholar]

- Z. Farkas, E. Országh, T. Engelhardt, S. Csorba, K. Kerekes, A. Zentai, M. Süth, A. Nagy, G. Miklós, K. Molnár, A systematic review of the efficacy of interventions to control aflatoxins in the dairy production chain – feed production and animal feeding interventions, MDPI: Toxins 14, 115 (2022) [CrossRef] [Google Scholar]

- FAO, What are mycotoxins? (2016)) http://www.fao.org/3/y1390e/y1390e02.htm (accessed Jun. 08, (2021) [Google Scholar]

- P. Singhal, S. Satya, S.N. Naik, Effect of different drying techniques on the nutritional, antioxidant and cyanogenic profile of bamboo shoots, Appl. Food Res. 2, 100036 (2022) [CrossRef] [Google Scholar]

- J. Huang, M. Zhang, Effect of three drying methods on the drying characteristics and quality of okra, Dry. Technol. 34, 900–911 (2016) [CrossRef] [Google Scholar]

- D.I. Onwude, N. Hashim, K. Abdan, R. Janius, G. Chen, The effectiveness of combined infrared and hot-air drying strategies for sweet potato, J. Food Eng. 241, 75–87 (2019) [CrossRef] [Google Scholar]

- X. Zhou, R. Li, J.G. Lyng, S. Wang, Dielectric properties of kiwifruit associated with a combined radio frequency vacuum and osmotic drying, J. Food Eng. 239, 72–82 (2018) [CrossRef] [Google Scholar]

- M.L. Magalhães et al, Drying intensification combining ultrasound pre-treatment and ultrasound-assisted air drying, J. Food Eng. 215, 72–77 (2017) [CrossRef] [Google Scholar]

- A. Chakraverty, Post Harvest Technology of Cereals, Pulses and Oilseeds (Oxford and IBH Publishing Company Pvt. Ltd, New Delhi, (2004) [Google Scholar]

- S. Kumar, S.V. Jadhav, B.N. Thorat, Life cycle assessment of tomato drying in heat pump and microwave vacuum dryers, Mater. Today: Proc. (2022). https://doi.org/10.1016/j.matpr.2021.12.333 [Google Scholar]

- A.S. Mujumdar, Some recent developments in drying technologies appropriate for postharvest processing, Int. J. Postharvest Technol. Innov. 1, 76–92 (2006) [CrossRef] [Google Scholar]

- B.O. Bolaji, A.P. Olalusi, Performance evaluation of a mixed-mode solar dryer (2008) [Google Scholar]

- A.B. Lingayat, V.P. Chandramohan, V.R.K. Raju, V. Meda, A review on indirect type solar dryers for agricultural crops – dryer setup, its performance, energy storage and important highlights, Appl. Energy 258, 114005 (2020) [CrossRef] [Google Scholar]

- A. Madhlopa, S.A. Jones, J.D.K. Saka, A solar air heater with composite–absorber systems for food dehydration, Renew. Energy 27, 27–37 (2002) [CrossRef] [Google Scholar]

- H.P. Bhavsar, Performance evaluation of various types of solar dryer and drying technologies, Int. J. Adv. Sci. Technol. 29, 6020–6032 (2020) [Google Scholar]

- I.T. Toğrul, D. Pehlivan, Modelling of thin layer drying kinetics of some fruits under open-air sun drying process, J. Food Eng. 65, 413–425 (2004) [CrossRef] [Google Scholar]

- V. Demir, T. Gunhan, A.K. Yagcioglu, Mathematical modelling of convection drying of green table olives, Biosyst. Eng. 98, 47–53 (2007) [CrossRef] [Google Scholar]

- J.K. Afriyie, Design, Simulation and Optimisation of a Chimney-Dependent Direct-Mode Solar Crop Dryer (CDSCD), De Montfort University (2007) [Google Scholar]

- J.K. Afriyie, M.A.A. Nazha, H. Rajakaruna, F.K. Forson, Experimental investigations of a chimney-dependent solar crop dryer, Renew. Energy 34, 217–222 (2009) [CrossRef] [Google Scholar]

- J.K. Afriyie, H. Rajakaruna, M.A.A. Nazha, F.K. Forson, Simulation and optimisation of the ventilation in a chimney-dependent solar crop dryer, Sol. Energy 85, 1560–1573 (2011) [CrossRef] [Google Scholar]

- J.K. Afriyie, A. Bart-Plange, Performance investigation of a chimney-dependent solar crop dryer for different inlet areas with a fixed outlet area, ISRN Renew. Energy 2012, 1–9 (2012) [CrossRef] [Google Scholar]

- J.K. Afriyie, H. Rajakaruna, M.A.A. Nazha, F.K. Forson, Mathematical modelling and validation of the drying process in a Chimney-dependent solar crop dryer, Energy Convers. Manag. 67, 103–116 (2013) [CrossRef] [Google Scholar]

- S. Zorya et al, Missing food: the case of postharvest grain losses in sub-Saharan Africa (2011) [Google Scholar]

- P. Chantawong, J. Hirunlabh, B. Zeghmati, J. Khedari, S. Teekasap, M.M. Win, Investigation on thermal performance of glazed solar chimney walls, Sol. Energy 80, 288–297 (2006) [CrossRef] [Google Scholar]

- A.G. Ferreira, C.B. Maia, M.F.B. Cortez, R.M. Valle, Technical feasibility assessment of a solar chimney for food drying, Sol. Energy 82, 198–205 (2008) [CrossRef] [Google Scholar]

- Z.D. Chen, P. Bandopadhayay, J. Halldorsson, C. Byrjalsen, P. Heiselberg, Y. Li, An experimental investigation of a solar chimney model with uniform wall heat flux, Build. Environ. 38, 893–906 (2003) [CrossRef] [Google Scholar]

Cite this article as: Anthony Agyei-Agyemang, George Yaw Obeng, John Kwasi Afriyie, Benjamin Atribawuni Asaaga, Effects of roof angle, inlet gap size and dryer height on temperature and relative humidity in a chimney-dependent solar crop dryer, Renew. Energy Environ. Sustain. 7, 18 (2022)

All Tables

Experimental matrix for effects of roof angle, inlet gap size and height on temperature.

The experimental matrix for effects of roof angle, inlet gap size and height on relative humidity.

The analysis of variance results for effects of roof angle, inlet gap size, and dryer height on temperature.

The analysis of variance results for effects of roof angle, inlet gap size and height on relative humidity.

All Figures

|

Fig. 1 Functional architecture and pictorial view of chimney-dependent direct mode solar crop dryer. |

| In the text | |

|

Fig. 2 Pareto chart of standardized effects (temperature response). |

| In the text | |

|

Fig. 3 Contour plot of temperature versus inlet gap and height and main effects plot for temperature. |

| In the text | |

|

Fig. 4 Interaction (Combine effects) plot for temperature. |

| In the text | |

|

Fig. 5 Optimization plot. |

| In the text | |

|

Fig. 6 Pareto chart of standardized effects (relative humidity response). |

| In the text | |

|

Fig. 7 Main effects plot, interaction (combine effects) plot and optimization for relative humidity. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.